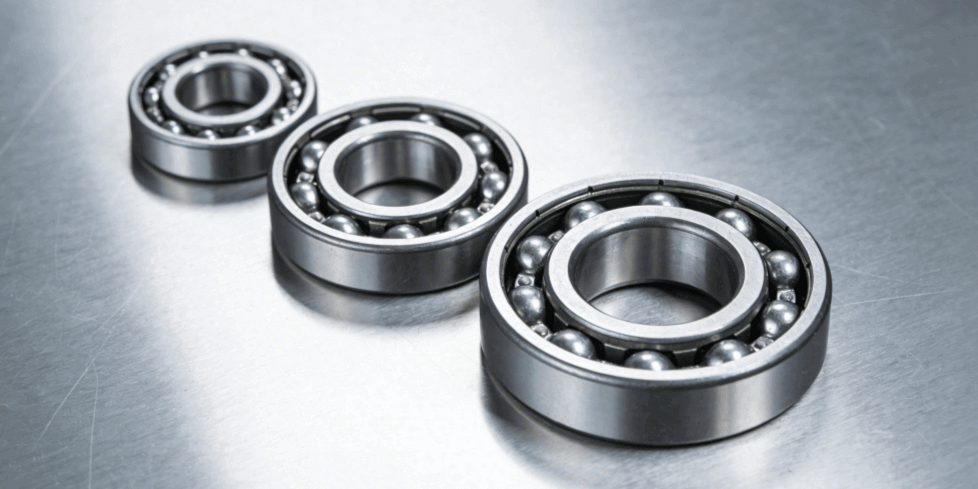

Selecting a Deep Groove Ball Bearing seems straightforward, doesn't it? They're the most common bearing type, found in everything from a desk fan to a factory conveyor. Yet, this very ubiquity is where many engineers and buyers trip up. Opting for a generic or incorrectly specified bearing is a shortcut to premature failure, unplanned downtime, and costly repairs. If you're sourcing bearings for motors, pumps, or machinery, you've likely asked: "Which model do I need, and what specifications actually matter?" The answer isn't always in the catalogue.

The core challenge is that 'deep groove ball bearing' is a category, not a one-size-fits-all solution. The performance and lifespan of your application hinge on the subtle details of a specific bearing's design and build. Let's move beyond the basic part number and explore the critical, often-overlooked factors that determine whether a bearing will merely fit, or truly excel.

The Workhorse Bearing: Where Deep Groove Ball Bearings Shine

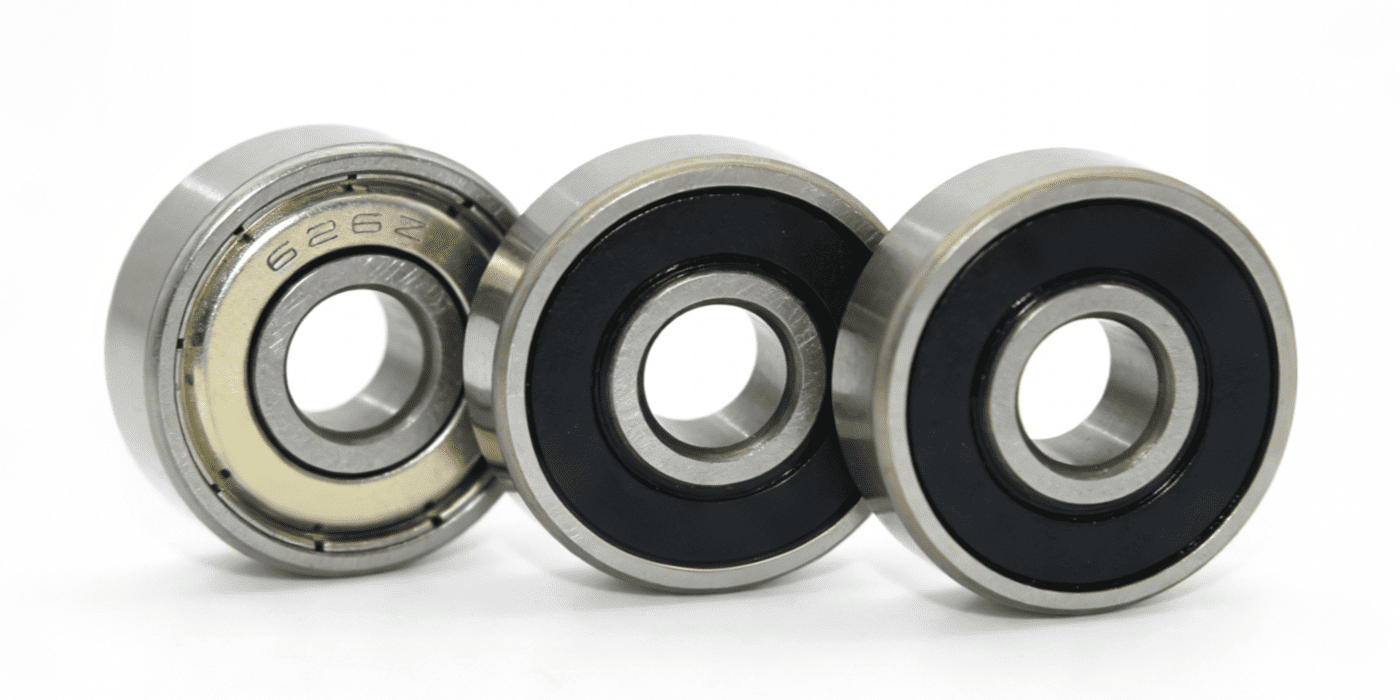

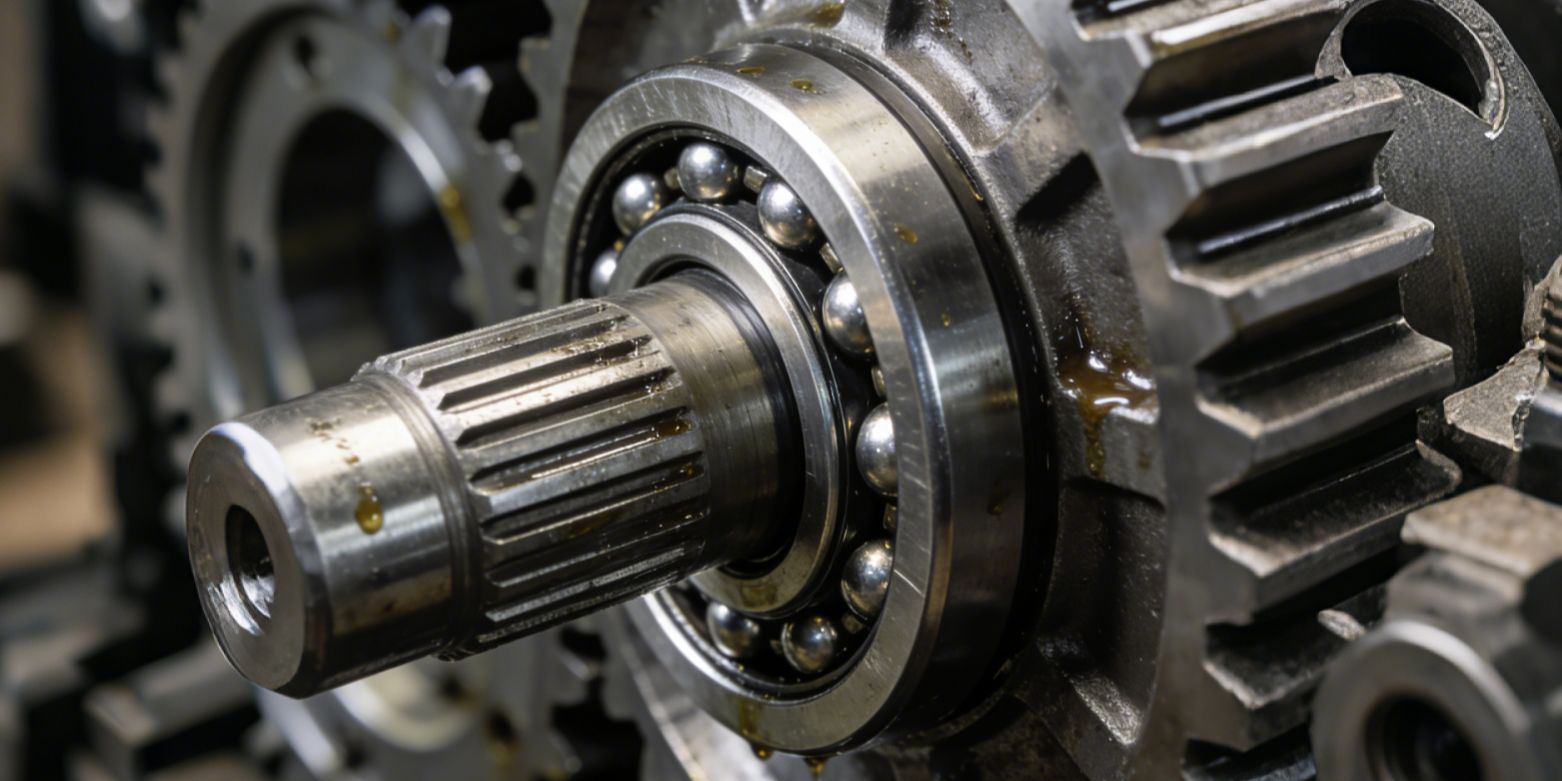

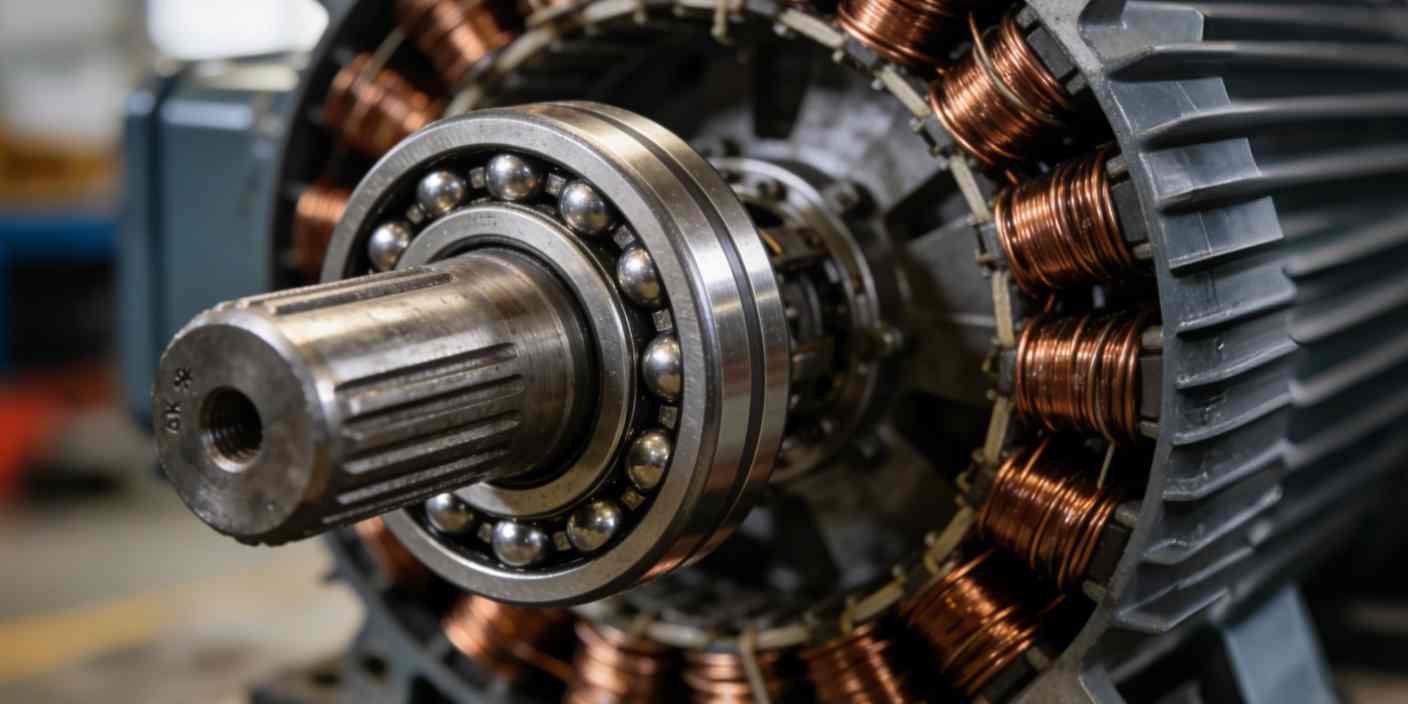

First, let's clarify why this bearing type is so prevalent. The deep groove ball bearing is the undisputed workhorse of industry. Its simple, versatile design, with deep, continuous raceways on both rings, allows it to handle significant radial loads and moderate axial (thrust) loads in both directions. This makes it incredibly adaptable.

You'll find them as the default choice in:

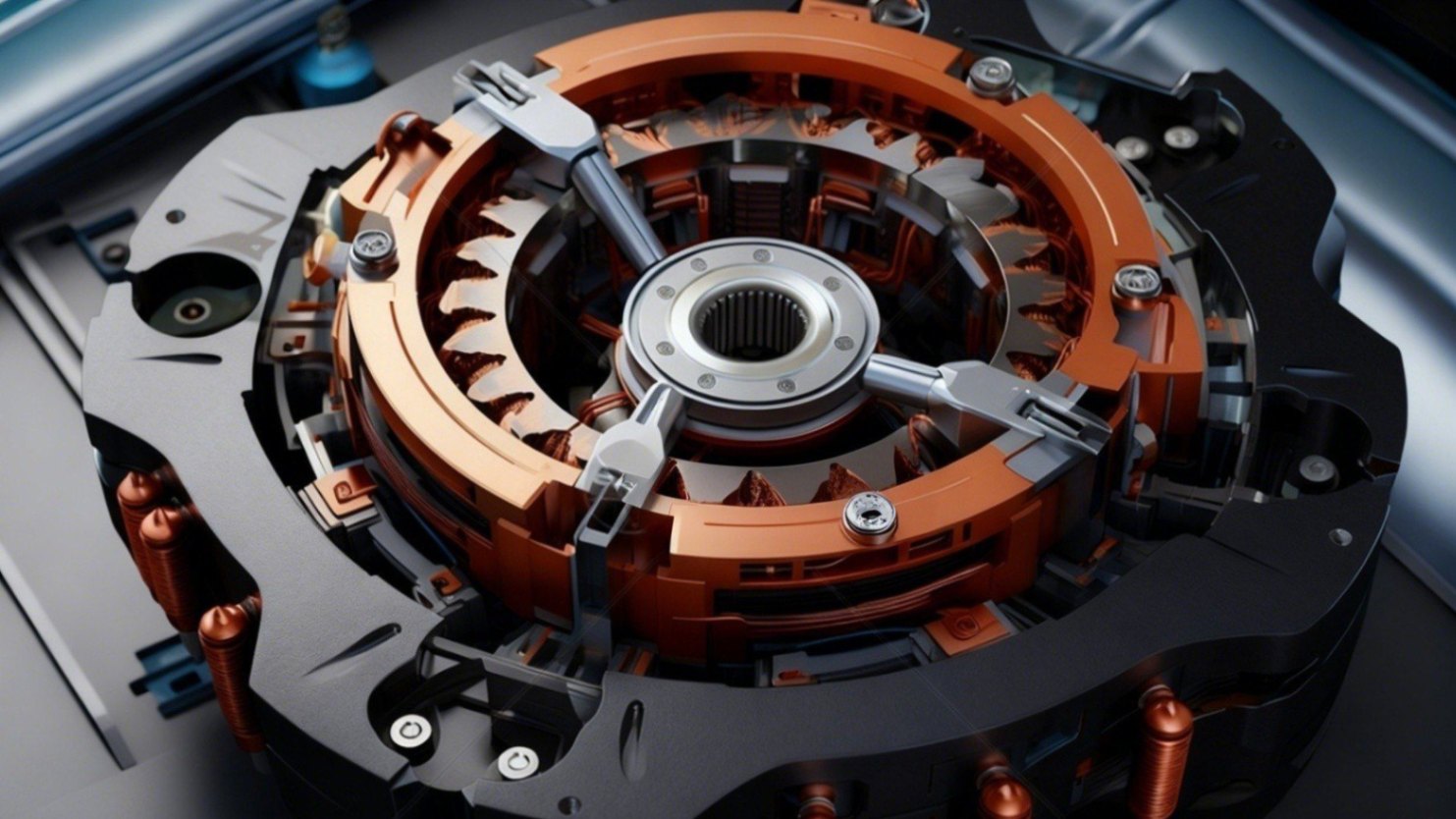

➊ Electric Motors (Induction, Servo, Gearmotors): Supporting the rotor shaft, where smooth, high-speed rotation is key, making high-quality Deep Groove Ball Bearings for Electric Motors essential for longevity.

➋ Pumps and Compressors: Withstanding constant radial loads from impellers whilst managing some axial thrust.

➌ Conveyor Systems: Supporting rollers under continuous, heavy radial loading in dusty environments.

➍ Agricultural and Automotive Equipment: Where robustness and reliability under variable loads are non-negotiable.

The pitfall begins when this versatility is mistaken for uniformity. Not all 6204 bearings, for example, are created equal.

The Hidden Pitfalls: Three Common Selection Mistakes

Mistaking a standard bearing for the right bearing leads to predictable failures. Here are the most frequent missteps we see.

1. Prioritizing Price Over Precision Grade

The Problem: You need a bearing for a new, efficient motor design. To save cost, you select a standard commercial-grade bearing (P0 or ABEC-1). Once installed, the motor doesn't meet its efficiency targets and emits a persistent, low hum. Vibration levels are higher than calculated.

Why It Happens: Lower precision grades have wider tolerances on raceway geometry, ball size, and surface finish. This increases internal friction (reducing efficiency) and generates more vibration and noise. In precision applications, it's like using budget tyres on a performance car, they fit, but they undermine the entire system.

The Solution: Specify a higher precision grade. For applications like motors, spindles, or medical devices, sourcing high precision deep groove ball bearings (specifically P5 or P6 grade) is essential. Manufacturers achieve this through precision grinding and 100% vibration screening (e.g., to V2 or Z3 groups). The result is smoother operation, lower torque, higher efficiency, and significantly reduced noise.

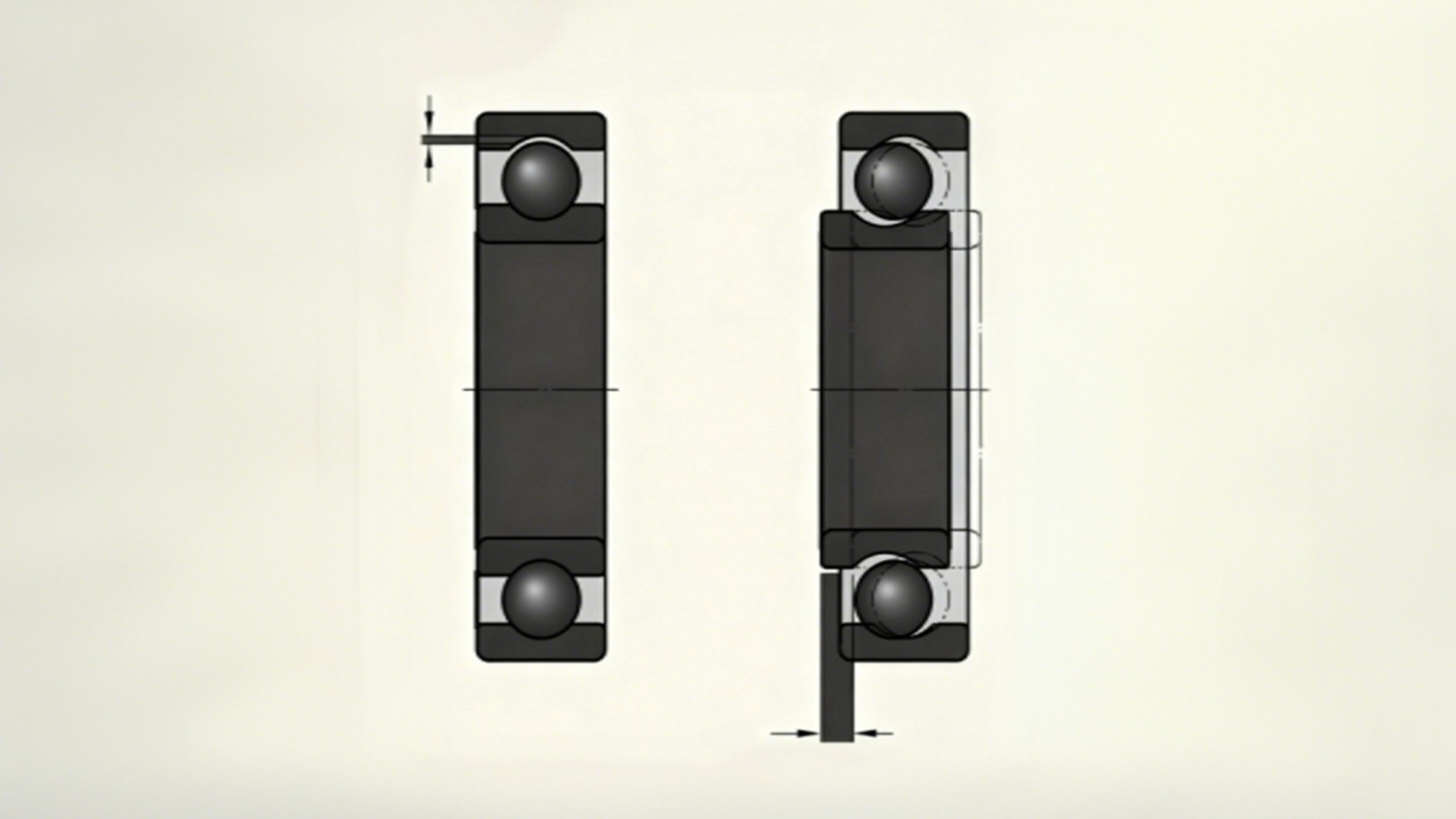

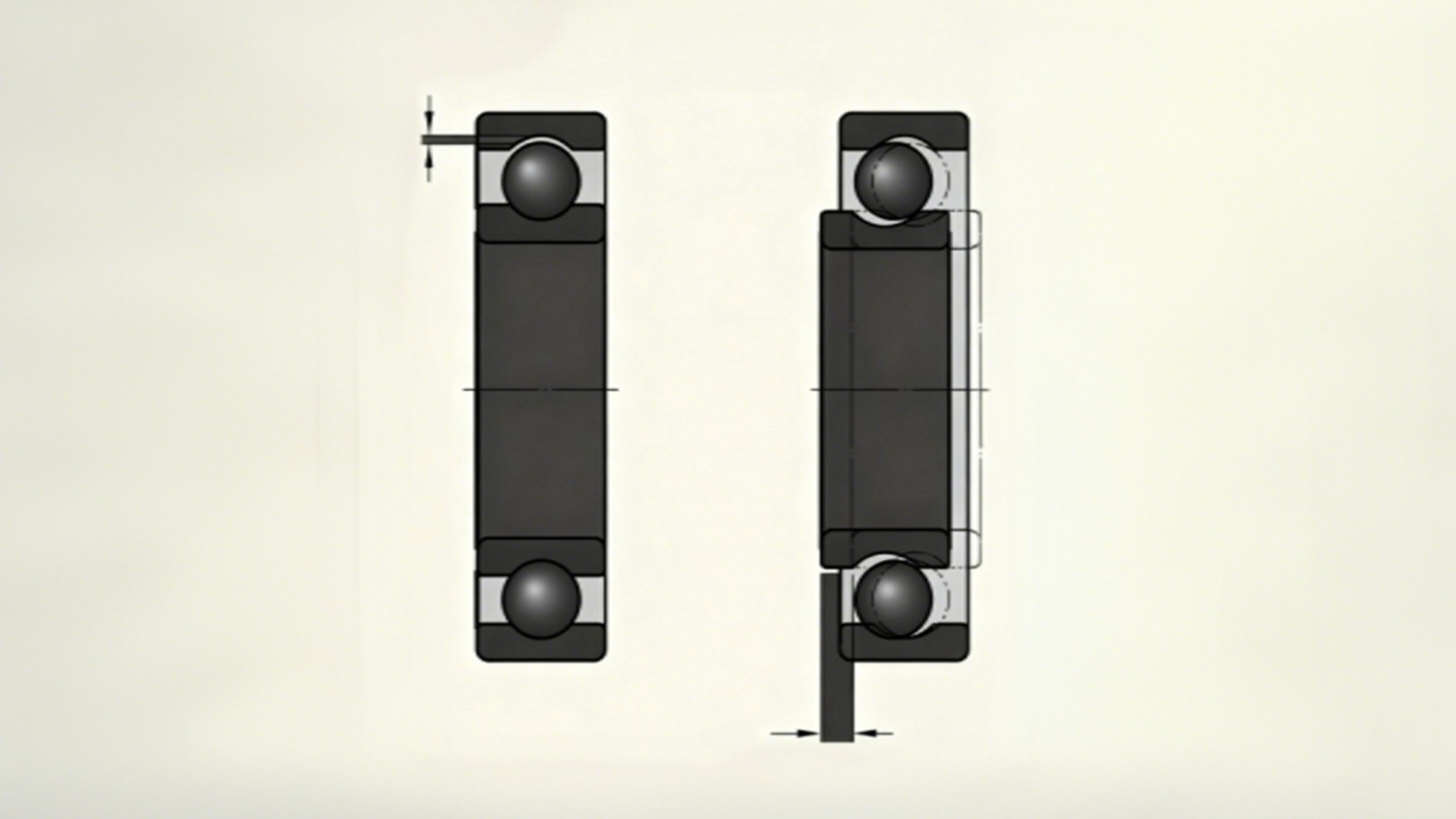

2. Ignoring the Crucial 'C' Code: Internal Clearance

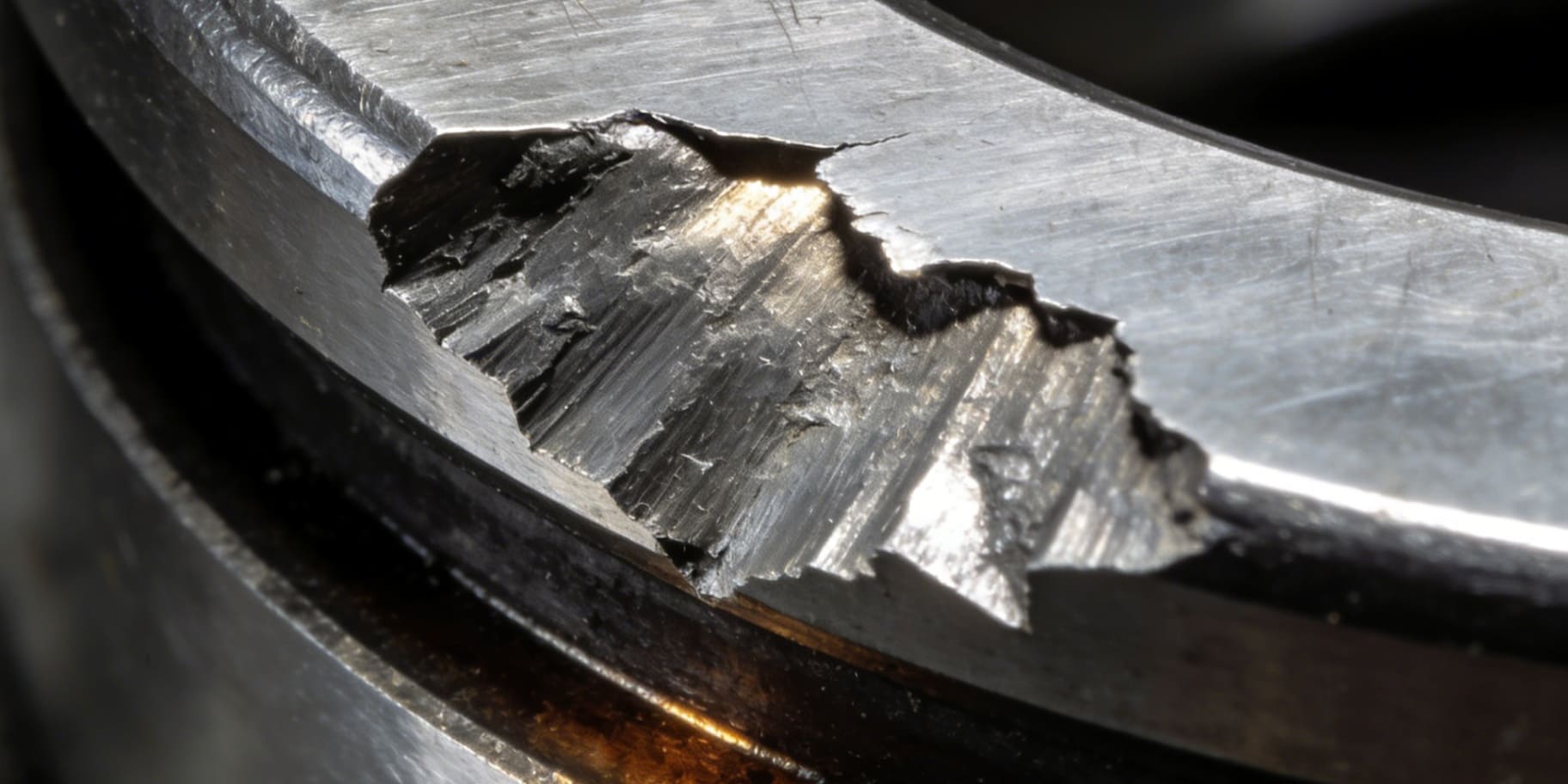

The Problem: A pump bearing fails repeatedly every few months, running hot and seizing. The replacement bearing is the correct model (e.g., 6205) but the failure pattern persists.

Why It Happens: This is a classic case of incorrect internal clearance. All bearings have a built-in internal clearance (play between balls and raceways). A standard clearance (C0) bearing installed in a system that heats up significantly during operation, like a pump or motor, will see that clearance vanish as the shaft expands. This creates a damaging preload, generating excess heat, accelerating lubricant breakdown, and leading to rapid failure.

The Solution: Understand thermal dynamics. For most rotating equipment, a C3 clearance (greater than standard) is recommended. This accommodates the thermal expansion of the shaft and housing, ensuring the bearing operates with the optimal internal play at its working temperature. Always consult the application's thermal profile when specifying clearance.

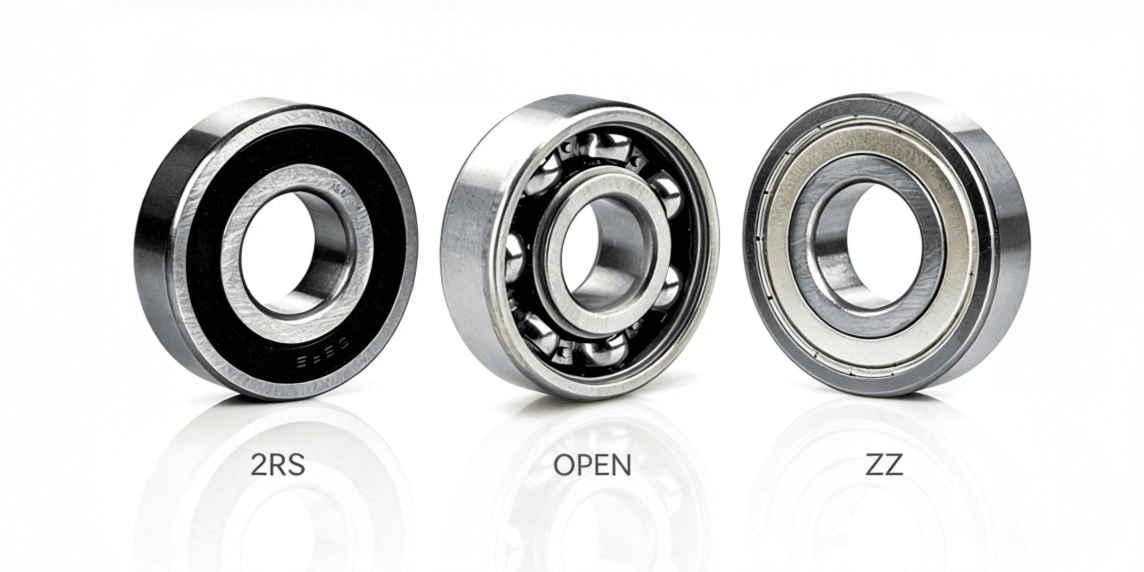

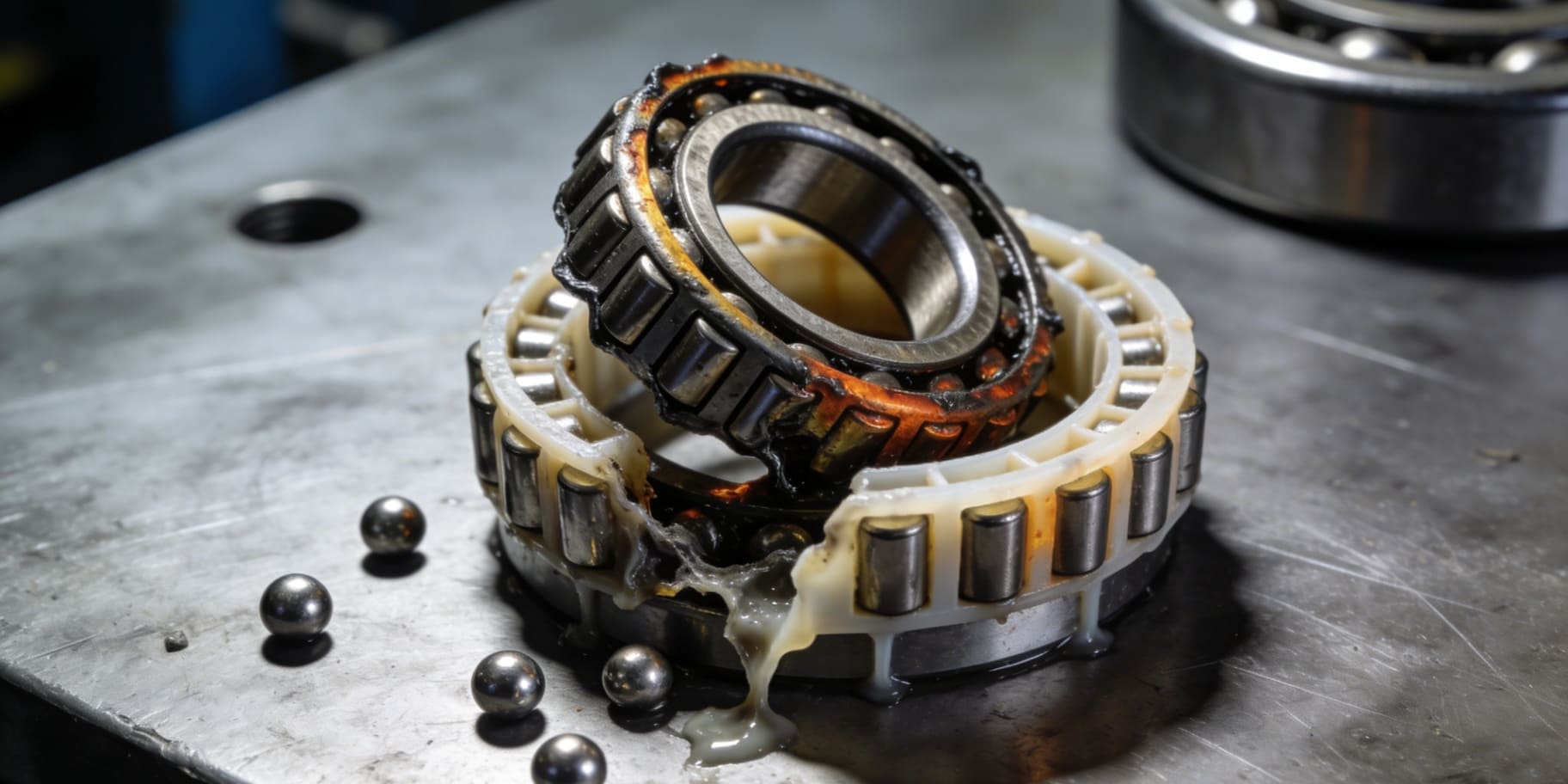

3. Choosing the Wrong Protection: Seals & Lubrication

The Problem: Bearings on a warehouse conveyor are failing prematurely due to grit ingress, despite being "sealed." Conversely, a high-speed spindle bearing is overheating because its seals create too much friction.

Why It Happens: The sealing and lubrication are the bearing's life support system. A metal shield (ZZ) offers minimal friction but is useless against fine dust or moisture. A standard contact rubber seal (2RS) protects well but increases rotational torque. Similarly, a general-purpose grease will oxidize annd fail in high-temperature or high-speed environments.

The Solution: Match the protection to the environment.

⚫ For clean, high-speed applications: Opt for non-contact seals or just metal shields.

⚫ For industrial environments (dust, moisture): Specify contact rubber seals (2RS or RS) to protect the integrity of the grease and keep contaminants out.

⚫ For lubrication: Don't accept a generic grease. Specify a high-quality, application-specific grease, be it a high-temperature stable grease for motors, a food-safe grease for packaging, or a corrosion-resistant grease for wash down environments.

Beyond the Catalogue: The Value of Technical Partnership

Choosing correctly requires more than just picking a number from a table. It demands an understanding of the application's nuances. This is where partnering with a specialist manufacturer pays dividends.

A quality manufacturer doesn't just sell bearings; they provide solutions. For instance, at Welink, our focus on core industrial series like the 6200 Series Deep Groove Ball Bearings and 6300 series means we build them with application-critical consistency. Our production is geared for repeatability: automated grinding and assembly ensure every 6206 or 6308 bearing meets its promised specifications. More importantly, we offer the essential customization, whether it's supplying a standard 6204 with C3 clearance and P6 precision, or advising on the optimal seal and grease for a harsh agricultural environment.

This technical dialogue can prevent costly errors. A five-minute conversation about your operating conditions can mean the difference between a bearing that lasts a year and one that lasts a decade.

Making the Informed Choice

The right deep groove ball bearing is a silent guardian of productivity. By looking beyond the basic model number and critically evaluating Precision Grade, Internal Clearance (C-code), and Sealing/Lubrication, you equip your application with a component built to last.

Before your next purchase, ask yourself: am I buying just a bearing, or am I specifying a performance-critical component? If it's the latter, the details we've outlined are not optional, they're fundamental.

For a detailed discussion on your specific application or to request technical data sheets for our deep groove ball bearing range, please contact our engineering support team at sales@welinkbearing.com.