In Africa, with the growing demand for clean drinking water and the development of the water packaging industry, bag water filling machines have become increasingly popular and offer significant advantages over bottled water filling machines.

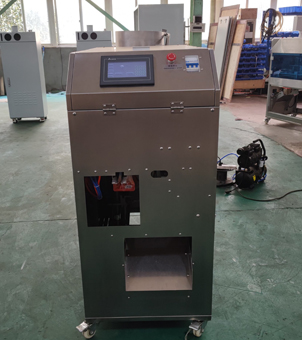

Lower Equipment Cost:

Compared to bottled water filling machines, bag water filling machines typically require a lower initial investment. For example, some high-performance bag water filling machines on the market cost approximately $1,000 to $5,000, while bottled water filling machines typically require a higher upfront cost due to their complex structure and advanced technology.

Lower Production Cost:

Sachet water machines use fewer materials than bottled water. The primary material for bagged water is plastic film, which is relatively inexpensive. In contrast, bottled water requires the purchase of plastic bottles, caps, labels, and other materials, which increases production costs. Furthermore, bag water machines typically consume less energy during operation. For example, some bag water machines have a rated power of only 1.6 kilowatts, further reducing production costs.

Reduced Transportation and Distribution Costs:

Bagged water is lighter and more compact, making it easier to transport and distribute. This reduces logistics costs and minimizes losses caused by bottle breakage during transportation. In parts of Africa where transportation infrastructure is underdeveloped, the lightweight and space-saving nature of bagged water makes it an advantage in distribution.

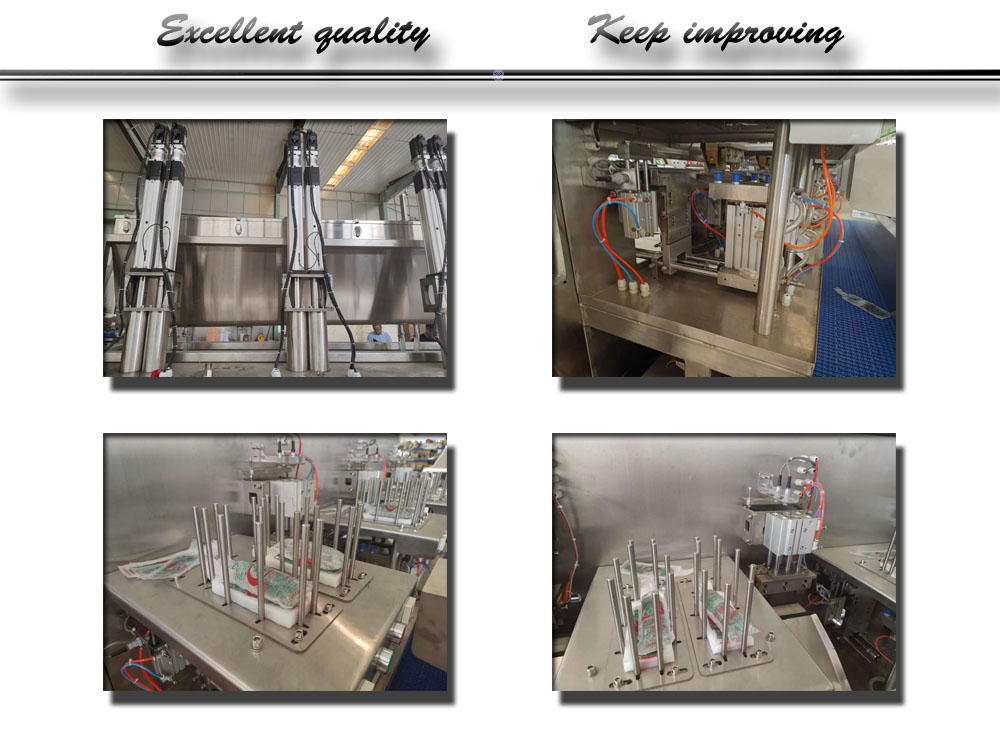

Flexible Packaging Sizes:

Water filling machines can accommodate a variety of packaging sizes, typically offering capacities from 50 to 500 ml, to meet diverse consumer needs. This flexibility allows businesses to adjust packaging sizes based on market demand and consumer preferences. Bottled water filling machines, on the other hand, are typically limited to specific bottle sizes, making switching between different capacities inconvenient.

Adaptable to Different Water Sources:

Water quality varies significantly across Africa. Bagged water filling machines can be equipped with simple filtration systems to adapt to different water sources and produce clean, hygienic drinking water. However, bottled water filling machines have more stringent water quality requirements and typically require more complex and expensive water treatment equipment to ensure the quality of the bottled water.

High Consumer Acceptance:

Bagged water is widely accepted in the African market. In many African countries, bagged water has become a popular choice due to its convenience, affordability, and compatibility with local consumer lifestyles. For example, in the Accra-Tema metropolitan area of Ghana, bagged water consumption has surged over the past decade, filling a critical gap in household water security. In contrast, bottled water is often viewed as a higher-end product, which limits the purchasing power of some consumers.

Strong Market Potential:

As Africa's population grows and living standards improve, the demand for clean drinking water continues to rise. Bagged water, as an affordable and convenient option, holds significant market growth potential. Entrepreneurs and businesses can leverage bagged water machines to quickly enter the market and capture a larger share of the drinking water market.

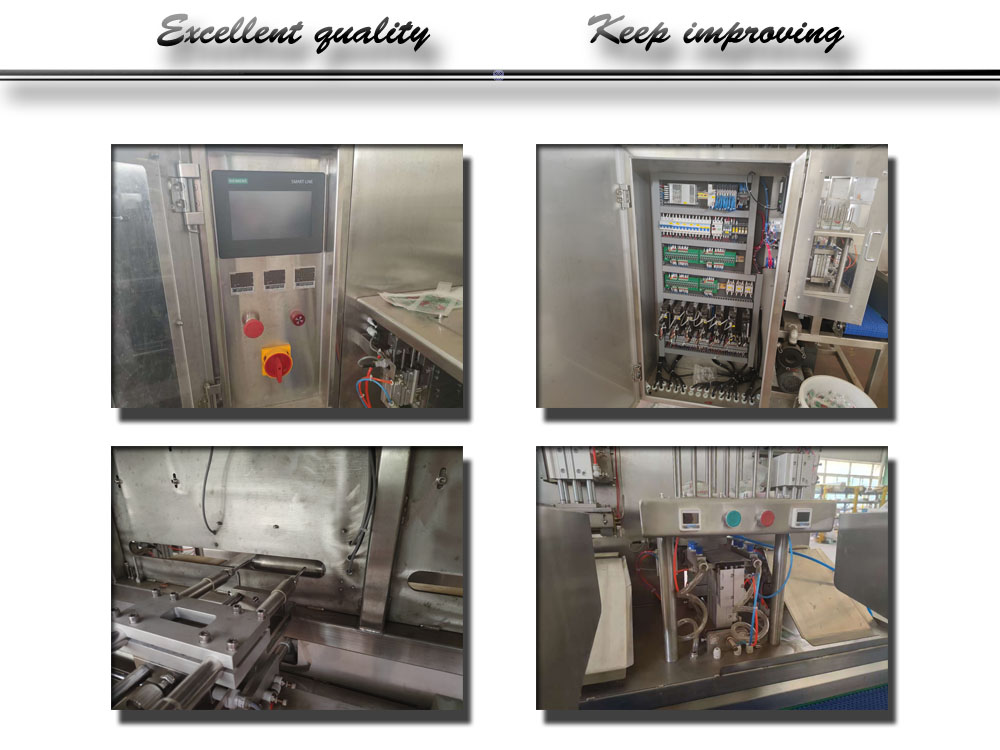

Easy Operation:

Bag filling machines feature a user-friendly design. Their one-touch control interface and automated features make them easy to operate, even for workers with minimal technical training. This reduces operational complexity and training costs for businesses. However, bottled water filling machines typically require higher levels of skill and technical knowledge.

Low Maintenance Cost:

Bag filling machines typically have a simple structure with fewer mechanical parts, resulting in lower maintenance requirements. Routine maintenance mainly involves cleaning and replacing easily worn parts, which helps ensure stable machine performance and reduce downtime. Bottled water filling machines have complex mechanical and electrical systems and require more frequent and professional maintenance.

In the African market, bagged water filling machines offer numerous advantages over bottled water filling machines, including cost-effectiveness, flexibility, adaptability, market demand, ease of operation, and environmental sustainability. These factors have made bagged water filling machines the preferred choice for many water producers and entrepreneurs. As Africa's economies develop and the demand for clean drinking water grows, bagged water filling machines will play an even more critical role in providing safe and affordable drinking water to the region's population.