A practical guide for RV owners and B2B buyers (with a few laughs and a lot of solutions)

The Mysterious Case of the Click-Click-Drip

Imagine this: You’re finally parked at that dream campsite, the awning’s out, the grill is sizzling, and you step inside your RV for a quick handwash… click-click… nothing. No water. Maybe just a disappointing dribble. You head to the water pump—click, again. The pump is cycling, but it’s not building pressure, and your faucets are staging a quiet protest.

If this sounds familiar, you’re likely dealing with a pressure switch problem in your fresh water pump. Whether you're an RV weekend warrior or someone outfitting a fleet of camper vans, the health of your pump’s pressure switch is mission-critical.

What’s Really Going On Inside That Little Switch

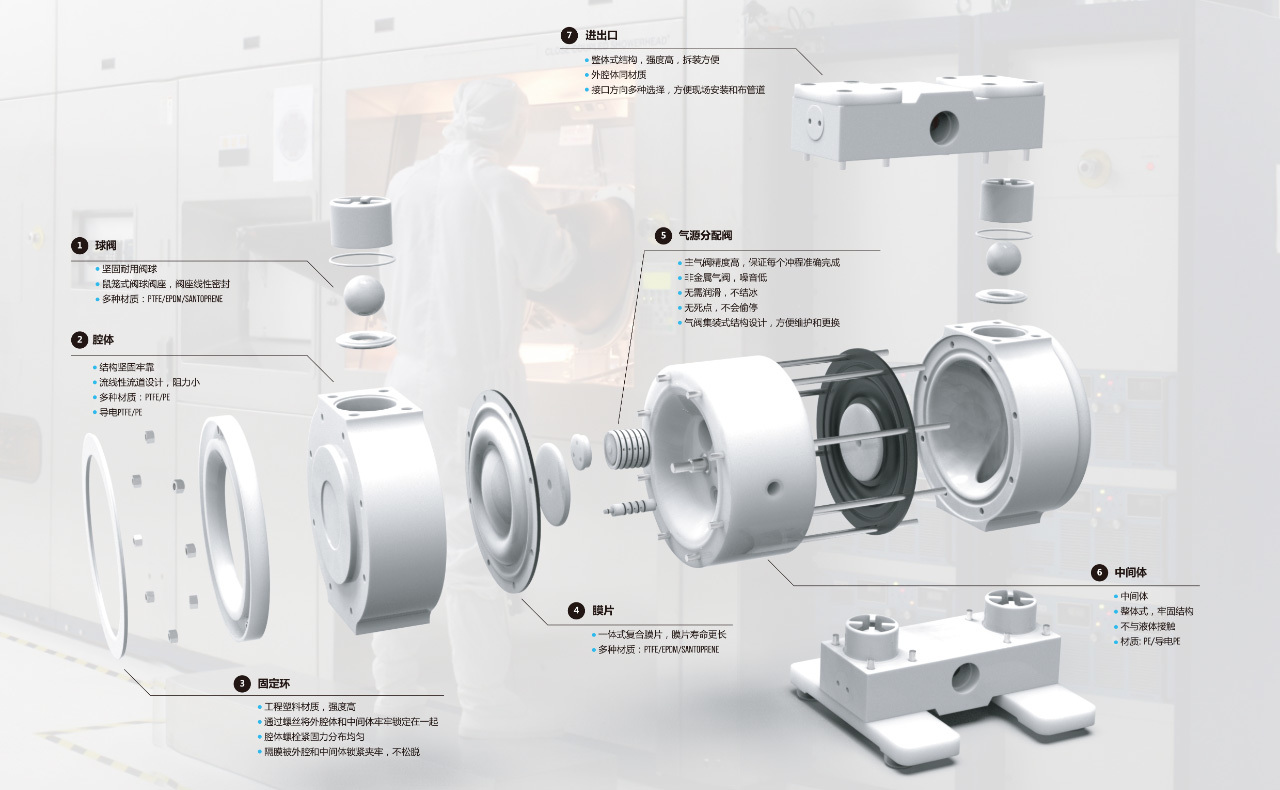

Let’s break it down. The pressure switch in your RV water pump is the tiny (but mighty) component that tells the pump when to turn on and off. Think of it as the thermostat of your water system—it responds to pressure changes, maintaining a sweet spot so water flows smoothly when you open a faucet and the pump shuts off when you're done.

When things go wrong, it’s usually due to one of the following:

Common Culprits Behind Pressure Switch Issues:

Debris in the system – Tiny particles clog the switch or valves, messing up pressure detection.

Worn-out diaphragm – Age or hard water can make it brittle and leaky.

Improper adjustment – The switch might be set too high or low for your system.

Electrical issues – Loose wires or corroded terminals can lead to intermittent operation.

Pump fatigue – If the pump itself is on its last legs, the switch won’t perform miracles.

Pro tip: If your pump runs non-stop or cycles quickly even when no faucets are open, your pressure switch is waving a white flag.

How to Fix (or Replace) That Pesky Pressure Switch

Here’s the part you came for—how to get your RV water system back in top form without calling in a full-blown repair crew.

Step 1: Confirm It’s the Switch

Before you blame the pressure switch, rule out easier fixes:

Check for leaks in the water system (hoses, joints, faucets).

Ensure your freshwater tank isn’t empty (hey, it happens).

Clean the pump strainer—gunk builds up fast.

If all that checks out, it’s time to inspect the pressure switch.

Step 2: Clean or Replace the Switch

Turn off the power to the water pump (usually a switch near your control panel).

Relieve system pressure by opening a faucet.

Remove the pump cover to access the pressure switch—usually located at the rear of the pump.

Inspect for debris, cracks, or signs of wear. Clean gently with a soft brush or compressed air.

Still acting up? You may need a replacement.

Step 3: Install a New Pressure Switch or Pump

If the switch is faulty, you can replace just the switch if your model allows it. But for many RV pumps, it’s often more practical (and future-proof) to replace the entire pump.

And this is where Newmao’s RV water pump lineup shines.

Why Choose a Newmao Fresh Water Pump?

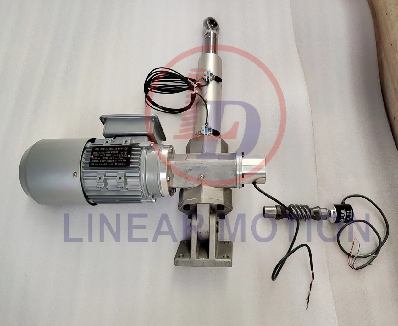

Our pumps are built for real-world RV use—quiet, efficient, and yes, pressure-switch friendly.

Advantages of Newmao RV Pumps:

✅ Reliable pressure switch pre-calibrated for most RV setups.

✅ Self-priming and run-dry protection for stress-free operation.

✅ Durable diaphragm construction resistant to wear and water quality.

✅ Compact, easy-to-install design (with mounting brackets included).

✅ Whisper-quiet motor so your midnight bathroom break doesn’t wake the campground.

You get performance, peace of mind, and fewer “why-is-there-no-water” meltdowns.

Bonus Tips for Keeping Your Pressure Switch Happy

Use a water filter between your tank and pump to block sediment.

Winterize your system properly—frozen switches are dead switches.

Run the pump monthly, even in off-season storage, to keep seals flexible.

Don’t ignore short-cycling—it’s a warning sign, not a feature.

Final Thoughts: Pressure Doesn’t Have to Be Stressful

If your fresh water pump pressure switch is misbehaving, you don’t need to panic—or suffer through another low-pressure shower. A little diagnosis, a bit of elbow grease, and the right replacement part (or pump) can have you back to glamping glory in no time.

Ready to Upgrade Your RV Water Pump?

Don’t wait for your next campsite surprise. Explore Newmao’s high-quality RV water pumps, designed for performance and built to last. Whether you're replacing a faulty switch or looking for a quieter, more efficient system—Newmao has your back (and your plumbing).